More Drawings, SpecificationS & Decisions

With planning approval under our belt, the project is officially handed to the Border Oak Technical Design Team and Contracts Team.

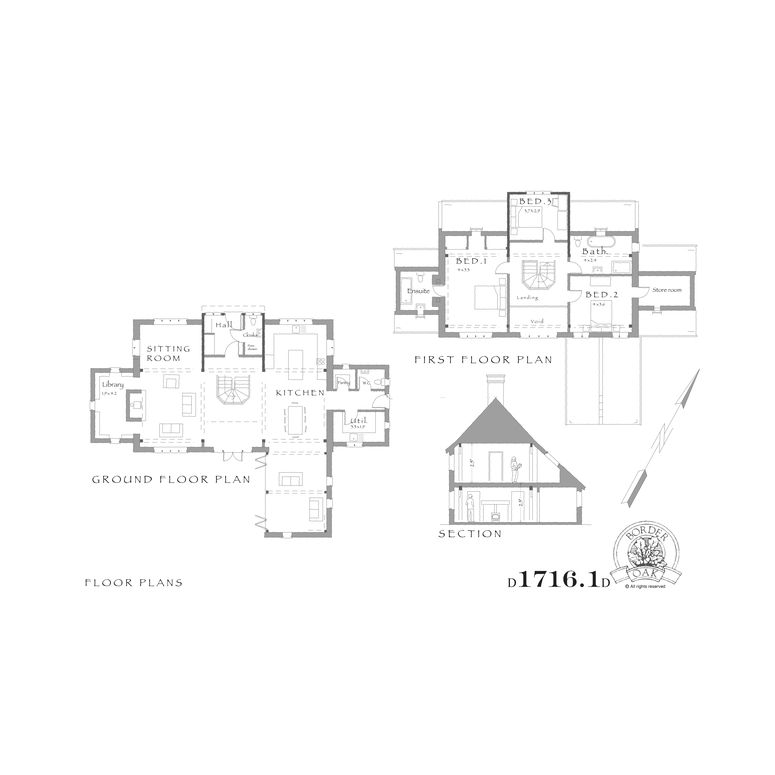

They began the tricky task of extrapolating the various layers of the project and translating the planning drawings into technical working drawings, engineering drawings, construction notes plus Building Regulation drawings and oak frame drawings (and the all important ‘cutting list’ to be sent off to our partner suppliers).

It’s impossible to really explain how much work goes into this part of any of our projects – it is incredibly complicated and thoughtful and requires significant experience and knowledge. Our highly skilled draughtsmen and engineers are used to bespoke work (every Border Oak house is different) but because we also make our frames (by hand) and construct what we have designed, we have a unique understanding of oak framing and how it interacts with all other materials and methods on site – not many can offer this.

This part of the design process uses modern technologies and computer aided design programs but also takes a team to complete well.

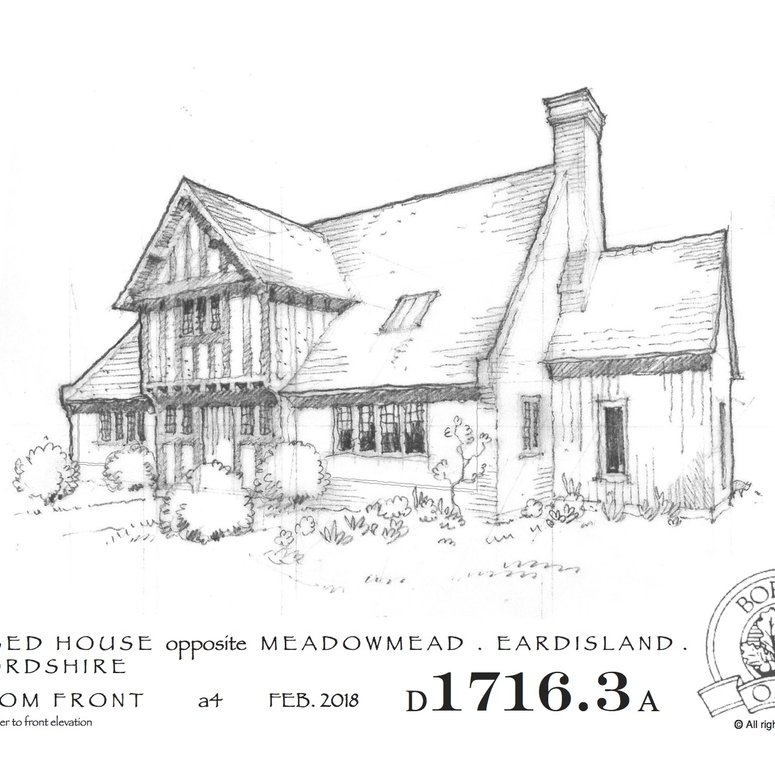

Whilst it is always a complex process, it was especially tricky on a house such as this where there are multiple different materials, unusual detailing and irregular processes. The house has has an open plan ground floor (without internal divisions for structural support), an intricate roof, a 700mm suspended floor and unusual architectural detailing such as the deep eaves and bracketed gutters.

But without the various sets of drawings it is very difficult for our other teams to make anything, calculate anything, order anything or actually build anything! Everything relies upon the drawings sets.

The drawings contain everything – from underfloor heating layouts, to bathroom designs, corner junctions to encapsulation layers. The drawings are used for Building Regulations, insurance, quantities, procurement, manufacturing, interior design, drainage, utilities, landscaping and problem solving.

Whilst the design team make a start, the specification meeting is held to finalise all the details – we try to capture as much as we possibly can including floor coverings (crucial for setting floor levels), door handles, light switches, joinery detail and paint colours as well as staircase design, which way doors open, which bricks and tiles and mortar mixes and even kitchen layouts if known.

We appreciate that it is almost overwhelming to make these decisions all at once, so we try and make it a bit easier and more enjoyable by using our show house as an example of finishes, and also having a wide range of choices on display at our offices or from photos of past projects. We encourage people to compile images and products they like as we are keen to help create your dream home. We also have a fabulous ‘black book’ of contacts who can make stuff and find stuff.

As John knew exactly what he wanted the house to look like, the specification meeting was almost super quick and straightforward. Patsy and John were still undecided on the final interior finishes for all the rooms but enough of the major finished were agreed, with the smaller details left to confirm as the project progressed.

In the meantime the oak frame drawings were completed, the cutting list dispatched to our suppliers and the oak was ordered – ready for the workshop crew to create their magic.